Booster B060-45

A booster's main function is to provide pressurized water for our satellites. Our booster program makes it possible to choose exactly the solution needed to solve the individual cleaning task. The booster is chosen from the total water consumption for the number of satellites you want to use at the same time.

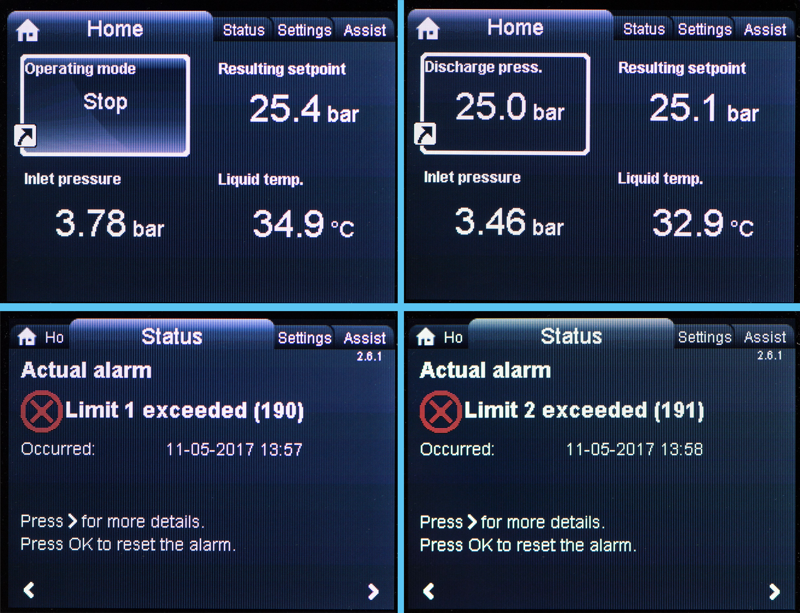

All boosters are equipped with the best energy-optimized motor-technology available from Grundfos (IE5). This also includes a built-in display which enables the user to read out multiple date. This makes it very easy for the operator or maintenance personel to locate any faults in the system (e.g. lack of water pressure).

Specifications

-

Simultanoues users

1

-

Pump pressure at 7 bar inlet pressure

45 Bar

-

Maximum water consumption

60 l/min

-

Minimum/maximum inlet pressure

2/10 bar

-

Maximum temperature

70 °C

-

Maximum power consumption

6 KW

-

Standard voltage

380-500V

-

Frequency

50-60 Hz

Performance highlights

-

0Simultaneous users

-

0L/min. - Maximum water consumption

-

0Bar - Outlet pressure at 7 bar inlet pressure

Flexible, intuitive, powerful and easy to use

-

Efficient

Less pressure loss means more cleaning power, which is equivalent to faster cleaning and less water usage.

-

High Quality

Engineered to last. Only high-quality components and high-grade stainless steel.

-

Long lifetime

The long lifetime of the product reduces the overall environmental impact.

Most Common Pump Alerts

-

Dynamic Outlet pressureOur booster stations are, in cooperation with Grundfos, optimized for Open Plan Cleaning in the Food & Beverage Industry. The pumps are constantly adapting to the number of users and available inlet pressure. This way we can ensure that our pump all the time will deliver at the hight possible efficiency.

Dynamic Outlet pressureOur booster stations are, in cooperation with Grundfos, optimized for Open Plan Cleaning in the Food & Beverage Industry. The pumps are constantly adapting to the number of users and available inlet pressure. This way we can ensure that our pump all the time will deliver at the hight possible efficiency. -

The green choiceEvery aspect of the satellite is designed and engineered to reduce the overall environmental impact of the satellite. High efficiency and a long lifetime reduce the total environmental impact significantly.

The green choiceEvery aspect of the satellite is designed and engineered to reduce the overall environmental impact of the satellite. High efficiency and a long lifetime reduce the total environmental impact significantly.

Related products

Industries where we make a difference

Don't hesitate to contact us

+45 22 50 39 00 foamico@foamico.com