Most Common Pump Failures

Satellite Repair Guides

Repair Guide - The Satellite does not Foam

Control the following:

• Is the Satellite in the Foam Position and is the correct nozzle mounted? (Nozzle with white protection)

• Is the chemical a Foam product?

• Is the Air pressure between 3-6 Bar?

• Is the water pressure to the Satellite at least 10bar?

• Is the Hose length below 30 meters, and at least ½”? A hose length above 30 meter can reduce the Foam quality.

If all the above has been checked but the Satellite still does not Foam control the following:

• Check the Chemical suction hose for cracks

• Control the Check valve for the chemical

- Remove the check valve and make sure that the small ball inside can move freely.

o This can be done with a piece of welding wire by pushing it into the check valve from below. Or by taking the check valve apart.

If the Satellite still does not Foam the Injector must be controlled.

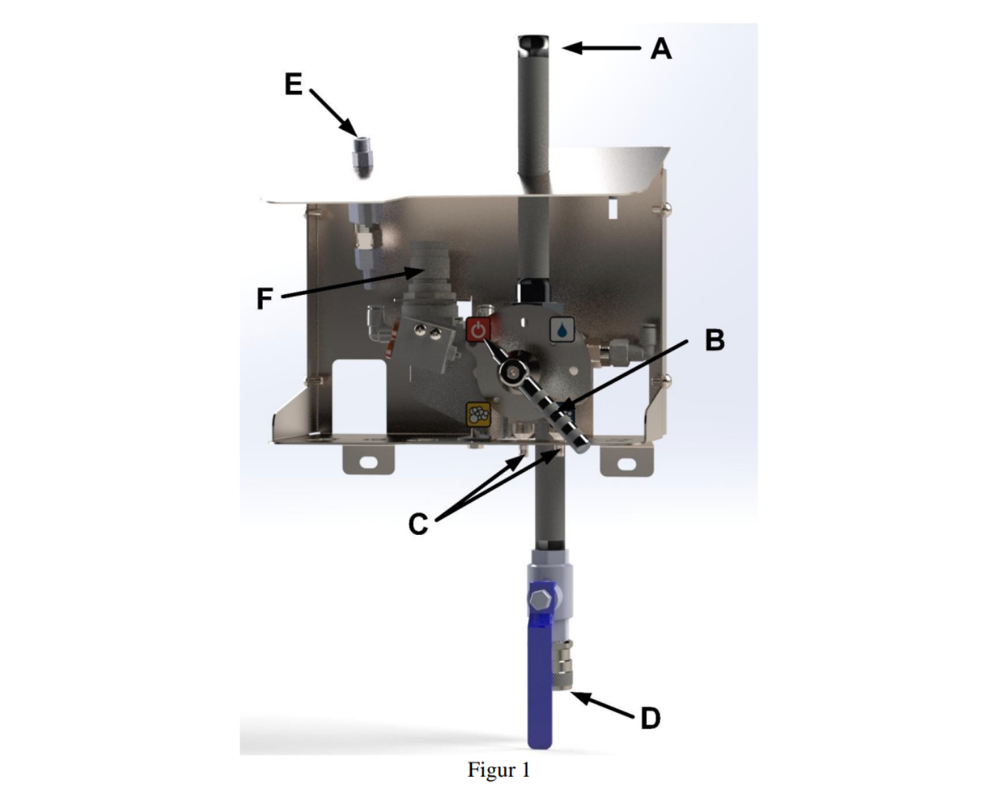

• Close the water inlet valve

• Take off the handle on the front and loosen the 4 screws holding the cabinet.

• Close the Air valve inside the Satellite

• Take off the air hoses so the Block can be removedfrom the cabinet.

• Loosen the union between the Block andthe water Inlet.

• Loosen the two screws underneath the Satellite

• Take the whole block out of the Cabinet

• Open the Block from the side where the Water in

and outlet is mounted.

• Take out the Injectors and make sure that they are not blocked by any chemical remains etc.

• Re-assamble the block and mount the block back into the Satellite.

If the Satellite still does not Foam contact a service technician.

SU Baseline Satellite

Main Station Service

Frequency Converter

Which product needs service?

-

MainstationsWall-mounted cleaning station with a built-in pump to supply itself and connected satellites with pressurized water.See solutions

MainstationsWall-mounted cleaning station with a built-in pump to supply itself and connected satellites with pressurized water.See solutions -

SatellitesSatellites are workstations for rinsing, foaming, and sanitizing. They must be supplied with pressurized water from a Mainstation or Booster.See solutions

SatellitesSatellites are workstations for rinsing, foaming, and sanitizing. They must be supplied with pressurized water from a Mainstation or Booster.See solutions -

Mobile StationsPortable cleaning stations including pump, compressor, and block technology for rinsing, foaming, and sanitizing.See solutions

Mobile StationsPortable cleaning stations including pump, compressor, and block technology for rinsing, foaming, and sanitizing.See solutions -

Automatic SolutionsAutomates the cleaning processes, reducing the total cleaning time and the tedious and physical hard cleaning tasks.See solutions

Automatic SolutionsAutomates the cleaning processes, reducing the total cleaning time and the tedious and physical hard cleaning tasks.See solutions -

BoostersProvides satellite workstations with pressurized water allowing multiple simultaneous users.See solutions

BoostersProvides satellite workstations with pressurized water allowing multiple simultaneous users.See solutions -

Prediluted SolutionsDilutes concentrated cleaning chemicals with water to a predetermined concentration, simplifying the cleaning process.See solutions

Prediluted SolutionsDilutes concentrated cleaning chemicals with water to a predetermined concentration, simplifying the cleaning process.See solutions