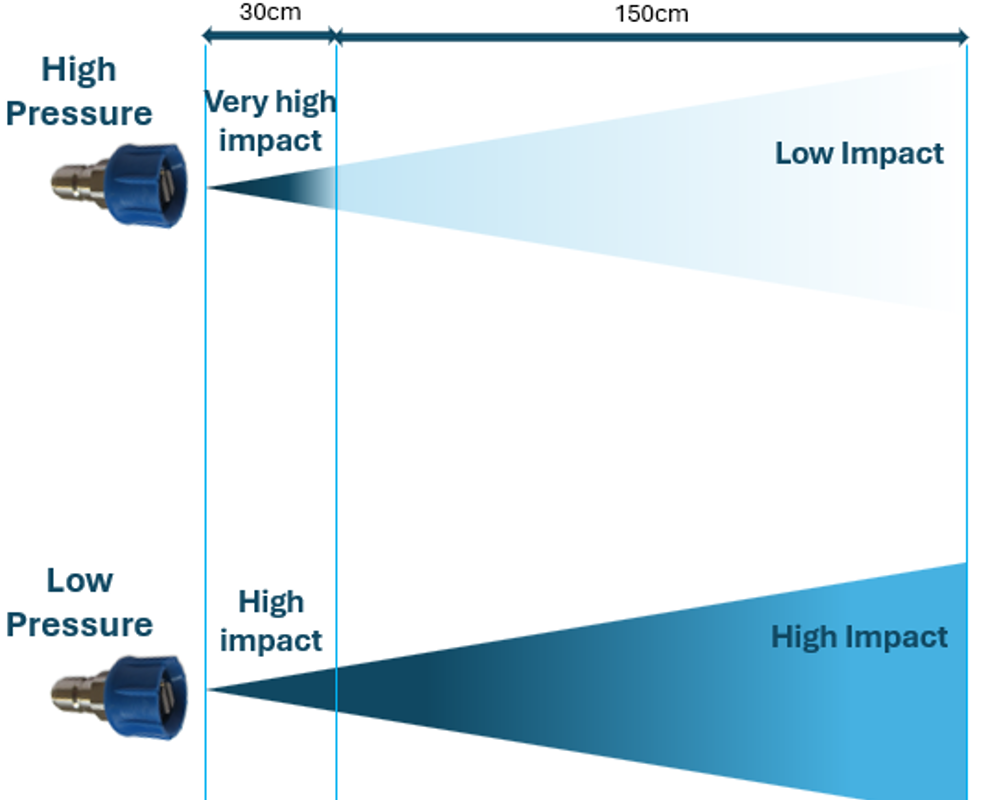

Foamico's low-pressure systems compared to high-pressure solutions

-

40%Reduction in cleaning time

-

60%Reduction in energy consumption

-

25%Reduction in water waste

Understand the Benefits of Low-pressure Cleaning Systems

Maximizing the benefits of low-pressure cleaning requires a thorough understanding of the technology and its applications. By using low-pressure cleaning systems, you can significantly improve your cleaning operations, ensuring better coverage, reduced surface damage, and improved safety. This approach also leads to more efficient use of water, in line with sustainability goals, while maintaining high hygiene standards in the food and beverage industry.

Low-pressure cleaning equipment includes specialized low-pressure valves, low-pressure washers, and nozzles designed to provide a precise, gentle cleaning action. These components work together to optimize the cleaning process and allow for the effective removal of contaminants without compromising the integrity of the surface. These units are built for durability and reliability, making them suitable for continuous use in demanding industrial environments.

Low-pressure cleaning is a professional heavy-duty cleaning method using low-pressure and high-flow systems. Our low-pressure cleaning systems can deliver up to 27 bar, while our medium-pressure systems can reach up to 45 bar.

Low-pressure valves and washers provide precise control and gentle cleaning, making them ideal for delicate surfaces. Low-pressure washers provide superior coverage and effective cleaning, reducing the risk of damage and increasing safety. By incorporating low-pressure cleaning systems, you can benefit from a more efficient, environmentally friendly cleaning process, which is essential for maintaining high hygiene standards in the food and beverage industry.

If you have any questions, please do not hesitate to contact us. Our specialists are dedicated to ensuring your cleaning needs are thoroughly addressed, providing you with expert guidance and support for your application.

Testimonial & Case Studies

Testimonial & Case Studies

Foamico Newsletter

Sign Up Today

Want to see what we can do for you?