Adapting to evolve

Our technology and innovation are based on striving to create the best possible solutions for our customers' needs.

To do this, we need to be flexible and adaptable because different customers have different challenges and needs. This vision is also reflected in our product selection.

Foamico's product range varies from main stations, satellites and customised boosters to small and influential accessories such as the right nozzle type for specific business cases.

Additionally, we offer automated, mobile and pre-diluted solutions. Once again, to be as flexible as possible.

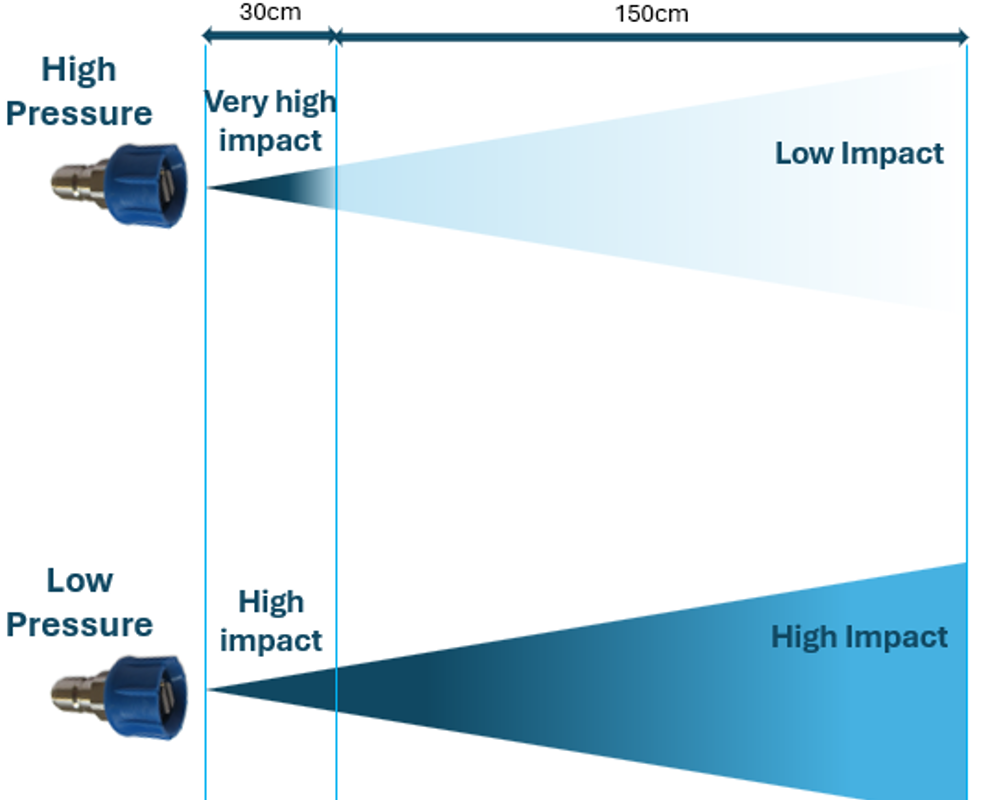

Foamico system compared to a high-pressure system

-

40%Reduction in cleaning time

-

60%Reduction in energy consumption

-

25%Reduction in water waste

Food Safety | Residue Build Up

Among the many cleaning challenges, residue has the potential to compromise food safety and hygiene in production facilties. Choosing the right cleaning tool is essential to minimising these challenges. While low-pressure cleaning solutions are gentle on surfaces and delicate components, they are highly effective, meaning they have the ability to prevent challenges such as residue build-up. By combining low-pressure technology with the right chemicals and contact time in food factory cleaning, food contamination is broken down at a molecular level, making it easier to remove.

Low-pressure cleaning also significantly reduces the risk of cross-contamination, including food and chemical contamination. The controlled water flow prevents the spread of dirt to other parts of the facility and ensures the effective elimination of allergens, harmful bacteria, and other contaminants.

This is particularly important in facilities where different food products are processed and cross-contact must be avoided to maintain food safety and quality while safeguarding public health.

Moreover, low-pressure cleaning is also more environmentally friendly than high-pressure methods. It uses less water, energy on water temperatures, and fewer chemicals, which not only reduces operating costs but also minimizes the environmental footprint.

This sustainable approach is consistent with the growing demand for environmentally friendly practices in food production.

Finally, the delicacy of low-pressure cleaning extends the life of the equipment. High-pressure cleaning can lead to wear and tear, resulting in expensive repairs and replacements. By choosing low-pressure solutions, food manufacturers can keep their equipment in great condition, ensuring consistent performance, reducing operational downtime and the risk of foodborne disease.

Food factory cleaning requires superior solutions and Foamico is here to create the best possible future for the health of your company's customers by ensuring quality food safety and hygiene in your cleaning practice.

-

Foamico Mobile Station

Foamico Mobile Station -

Conveyor Cleaning

Conveyor Cleaning

EFSA | Protecting the Food Business from Contamination

The European Food Safety Authority (EFSA) is an independent source of scientific advice on food risks.

EFSA advises on existing and emerging food risks. This advice informs European laws, regulations and policies - helping to protect consumers from risks such as foodborne illnesses and infectious diseases in the food chain.

Policies, laws and regulations cover many different areas of food production. For example, EFSA advice has led to specific hygiene rules for foods of animal origin, such as meat, poultry and fish, to prevent harmful bacteria contamination. There are also rules for certain levels of contamination in the food business, ensuring that both food products and the environment where they are processed remain safe and free from excessive bacterial or chemical pollutants.

It is extremely important to comply with these laws, policies and regulations when operating a food production facility.

Low-pressure cleaning technology can help ensure that there is no cross-contamination between production cycles, preventing foodborne diseases and other heavy consequences while at the same time using less water, labour, and energy in your food factory cleaning process.

HACCP | Reducing Risk of Foodborne Illness and Chemical Contamination

HACCP is a management system that addresses unsafe food by analysing and controlling biological, chemical and physical hazards from the production, procurement and handling of raw materials through to the manufacture, distribution and consumption of the finished product.

From growing, harvesting, processing, manufacturing, distributing and merchandising to preparing safe food, HACCP is designed for use in all segments of the food industry. Pre-requisite programs such as current Good Manufacturing Practices are an essential foundation for the development and implementation of successful HACCP plans.

Food safety systems based on the principles of HACCP have been successfully implemented in food processing plants, food retail outlets, and food service establishments.

The HACCP system consists of seven principles, all of which contribute to the guidelines of a food business, these principles cover everything from hygiene control to process monitoring.

It is essential for food manufacturers to comply with government regulations and ensure food safety and hygiene, which is done by using the right food factory cleaning equipment.

-

Spiral Freezer & Chiller

Spiral Freezer & Chiller -

Open Plant Cleaning

Open Plant Cleaning

Testimonials & Case Studies

Testimonials & Case Studies

Ready to Optimize Your Cleaning Process?

Fill out the form below to get tailored solutions and expert advice from Foamico. Let us help you enhance your cleaning process with our innovative industrial cleaning technology.

Want to see what we can do for you?