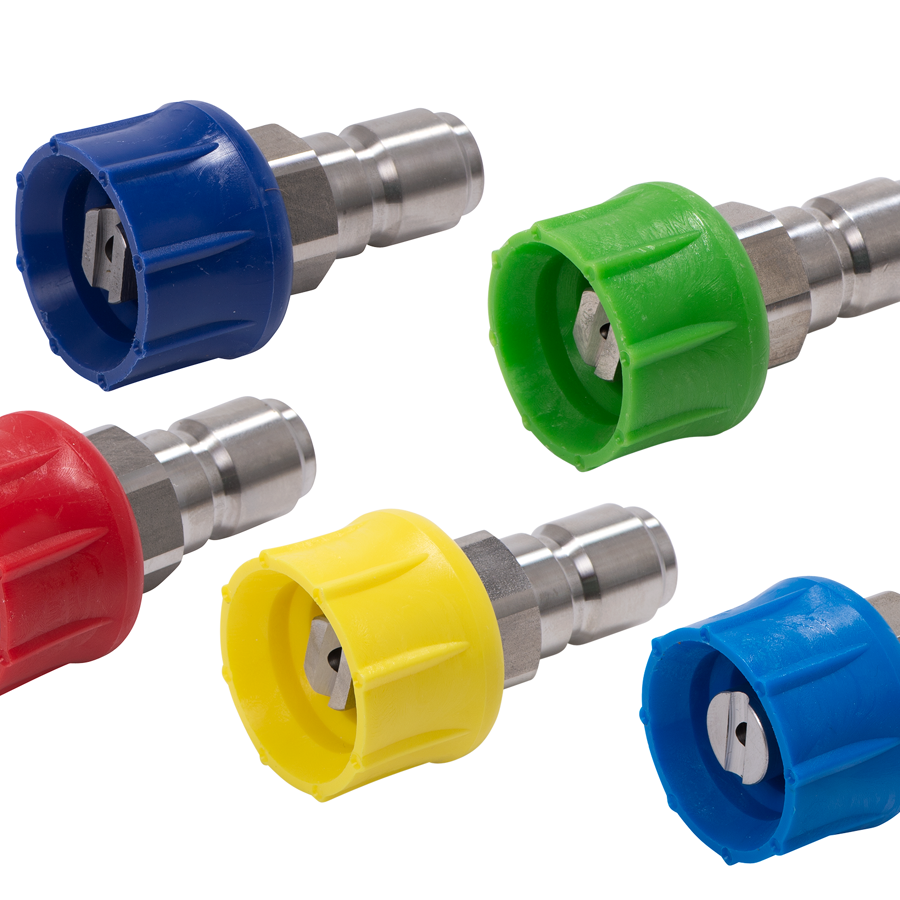

- "I tested 14 hose nozzles from four different suppliers, to see the exact difference in water consumption, distribution, impact and durability of the nozzle based on the nozzle protection design. All the tests were carried out at Foamico in Nørresundby with exactly the same set-up during all the tests, and I participated in all the tests myself - partly to ensure that everything was 100 per cent consistent and fair," says Lars Blirup.

After numerous tests with many different nozzles, one Foamico nozzle stood out.

"In order to get a fully comparable picture of performance, one particular Foamico nozzle stood out significantly from all the others, delivering a fantastic impact at only 34.5 litres per minute," says Lars Blirup.

-

Nozzle calculationsBased on this project carried out by Lars Blirup - Facility Consultant at Scandi Standard. At Foamico, we have calculated the various savings that can be achieved by reducing 7.5 litres of water per year. These calculations focus on the cost of heating water, the cost of water into the factory and the cost of water out of the factory.

Nozzle calculationsBased on this project carried out by Lars Blirup - Facility Consultant at Scandi Standard. At Foamico, we have calculated the various savings that can be achieved by reducing 7.5 litres of water per year. These calculations focus on the cost of heating water, the cost of water into the factory and the cost of water out of the factory. -

Total Cost SavingsBy using Foamico's 10/35 nozzle, this experiment shows that you can save a huge amount of water. Our calculations show not only a huge opportunity to implement the right cleaning to contribute to the bottom line, but also that the amount of water you save really makes a difference to the green transition. Heating cost savings for 1 year - € 18966,78 Cost saving for water to the factory 1 year - € 14075,59 Cost saving for water out of the factory 1 year - € 32172,77 Total savings - € 65215,14

Total Cost SavingsBy using Foamico's 10/35 nozzle, this experiment shows that you can save a huge amount of water. Our calculations show not only a huge opportunity to implement the right cleaning to contribute to the bottom line, but also that the amount of water you save really makes a difference to the green transition. Heating cost savings for 1 year - € 18966,78 Cost saving for water to the factory 1 year - € 14075,59 Cost saving for water out of the factory 1 year - € 32172,77 Total savings - € 65215,14

Testimonials & Case Studies

Testimonials & Case Studies

Ready to Optimize Your Cleaning Process?

Fill out the form below to get tailored solutions and expert advice from Foamico. Let us help you enhance your cleaning process with our innovative industrial cleaning technology.

Want to see what we can do for you?